Category:

Industrial antifoam, silicone defoamer, foam control, non-silicone antifoam, foam eliminator, industrial antifoam, biodegradable defoamer, antifoam additive, foam reduction, water treatment antifoam.

**The product images are for illustrative purposes only and may vary in their presentation, packaging, or container depending on availability and production requirements.

Industrial antifoam, silicone defoamer, foam control, non-silicone antifoam, foam eliminator, industrial antifoam, biodegradable defoamer, antifoam additive, foam reduction, water treatment antifoam.

We know that foam is not a minor detail — it’s a risk to the continuity of your operation. As your industrial antifoam supplier and technical partner, we don’t just sell you an additive; we give you back control, capacity, and efficiency in your production line.

Silicone-based liquid antifoam, immediate action, fast and stable dispersion for chemical, paper, and agrochemical industries.

Versatile antifoam solution that provides rapid, stable dispersion and immediate action. Controls foam efficiently in textile, chemical, paper, water treatment, and oil industries.

Silicone-based powder antifoam, safe and efficient, designed to control foam in food processing, fermentation, confectionery, and beverages.

Non-silicone antifoam made from aliphatic oils, offering efficiency, stability, and compatibility across multiple industrial processes.

Biodegradable defoamer formulated with ethoxylated alcohols and vegetable oils. Effective in chemical, textile, and water treatment industries.

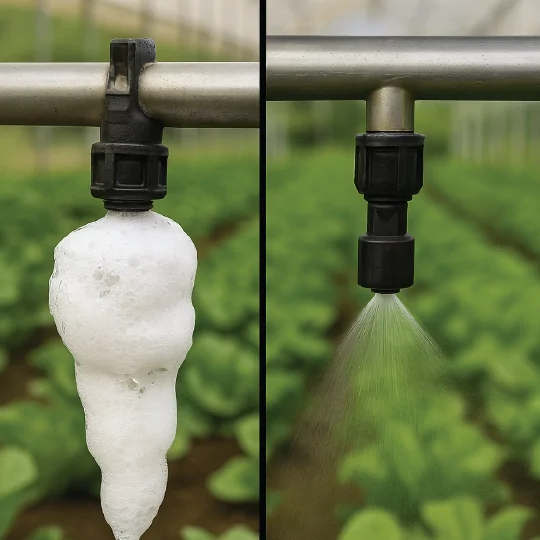

We understand the daily reality of companies dealing with foam-related processes. It’s not just about cleaning — it’s the inconsistent batch because trapped air altered the density. It’s the production line stoppage caused by a false sensor reading. It’s the loss of capacity in your tanks.

Whether your challenge lies in wastewater treatment or in the formulation of antifoams for detergents and soaps, uncontrolled foam is that hidden cost that directly affects your profitability. Our approach is not just to sell an antifoam — it’s to solve these challenges at the root.

Loss of Productive Capacity

Foam steals up to 15% of the useful volume in your tanks, forcing you to operate below real capacity and extending production cycles.

Unplanned Line Downtime

Spills create safety risks, sensors give false readings, and pumps cavitate. Each of these failures — caused by foam — stops your operation.

Batch Inconsistency and Rejection

Trapped air (micro-foam) alters the density, texture, and dosage of your product. The result: inconsistent filling and batches that fail to meet specifications.

In a market full of generic distributors and one-size-fits-all imported solutions, Zerachem stands out for one simple principle: we are manufacturers, and our laboratory is an extension of yours.

We don’t believe in passive solutions. We believe in chemical excellence that translates into active and predictable process control. This means:

Purposeful Formulation: Every antifoam we develop is designed not only to collapse foam, but to release trapped air, addressing the root cause of inconsistency.

True Agility: Need a reformulation for your paint antifoam or an adjustment for your paper industry process? Our R&D laboratory responds in days, not months.

Absolute Traceability: We guarantee batch-to-batch consistency in our solutions, removing the “supplier” variable from your problem equation.

On-Site Technical Support: Our real work begins when the product reaches your production line. We accompany your process to ensure the solution performs in your reality — not just ours.

Our experience translates into a portfolio of precise solutions, not off-the-shelf formulas.

Our Antifoamzera I20 and I30 line is more than just an industrial antifoam — it’s your shield in pharmaceutical, industrial, oil, and agrochemical processes, ensuring micro-foam elimination for perfect batch consistency.

For Specific Processes: Chemistry That Adapts to You

For challenges like wastewater treatment or foam control in paper production, our Antifoamzera I30 and the Non-Silicone version (based on aliphatic oils) deliver superior performance without compromising the integrity of your final product.

For Dry Processes: Intelligent Chemistry in Solid Form

Our industrial powder antifoam, Antifoamzera Powder, provides a technical advantage for detergent manufacturers and the agricultural antifoam sector. Its precise dosing and controlled activation eliminate waste and optimize efficiency.

For Oil & Gas: High-Resistance Formulations

We understand extreme conditions. From tank-filling foam control to drilling mud and gas antifoam formulations, we design robust solutions that ensure the safety and efficiency of your operation.

¿Hablamos? con nosotros tienes un equipo que se preocupa realmente por entender la causa raíz de la inestabilidad y nuestro laboratorio trabaja en una formulación ágil y a la medida.

¡Hagamos química juntos! Te invitamos a una sesión de sinergia técnico de 30 minutos. No es una presentación de ventas. Es un diálogo directo para analizar el desafío de control de espuma y trazar juntos una ruta de solución que impacte directamente tu operación.

Let’s talk — with us, you have a team truly committed to understanding the root cause of instability, while our laboratory works on an agile, customized formulation tailored to your process.

Let’s create chemistry together!

We invite you to a 30-minute technical synergy session — not a sales pitch, but a direct dialogue to analyze your foam-control challenge and build a solution roadmap that directly impacts your operation

Publicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelente atención. Excelente servicio, el proceso de presentación y el seguimiento post venta es lo que me permite confiar en esta compañía. Gracias de nuevoPublicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelentes sus productos y asesoría, 100% recomendadoPublicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelente servicio 👍Publicado enTrustindex verifica que la fuente original de la reseña sea Google. Productos de excelente calidad personal súper profesional y cordial!!! Gracias Andrés Ruiz súper cordial y profesionalPublicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelentes productos! Y el vendedor David Ruiz muy buen comercial, los felicito 👏🏼👏🏼👏🏼Publicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelente servicio del señor David Andrés Ruiz y en general!!! con unos productos altamente calificados y gran cumplimiento.Publicado enTrustindex verifica que la fuente original de la reseña sea Google. Excelentes productos y excelente servicio. 🙂Publicado enTrustindex verifica que la fuente original de la reseña sea Google. La atención por el asesor andres ruiz fue bastante clara y óptima, excelente atencion

Agile reformulation, local support and on-site assistance.

Stock and controlled deliveries.

Complete regulatory documentation.

Real technical sustainability.

We understand what your day-to-day looks like: a raw material that changes without warning, a batch that doesn’t meet specifications, the constant pressure to optimize costs and avoid reprocessing. Your process is unique, and a standard off-the-shelf solution is simply not enough.

That’s why we’ve designed our portfolio not to fit into a list, but to solve your problems.

Do you already know which component you’re looking for?

Here you have direct access to our line of specialties: antifoams, emulsions, degreasers, and more.

Are you looking to solve a challenge in your industry?

Explore the solutions we’ve already formulated for the specific challenges of your sector (food, pharmaceutical, agro-industrial, automotive, oil & gas).

Describe your needs and let’s get the plan started: technical diagnosis, samples for your validation and approval, along with support to implement the raw material that best fits your needs and process.

We’re ready!